The quality, availability, convenience and price of briquettes appear to be major factors hindering widespread adoption of briquetting technologies in sub-Saharan Africa. In addition, dependency on importation of equipment, spare parts and after-sale services limits the scale at which briquetting production can occur and, to a large extent, explains why there are few briquetting factories in the region.

Like in pelleting, husk briquetting requires a husk grinder, mixer and the briquetter. AfricaRice-TCMS grinder, Mixer and Multi-functional Screw Press briquetter/Pelleter can also be used for husk briquetting processes.

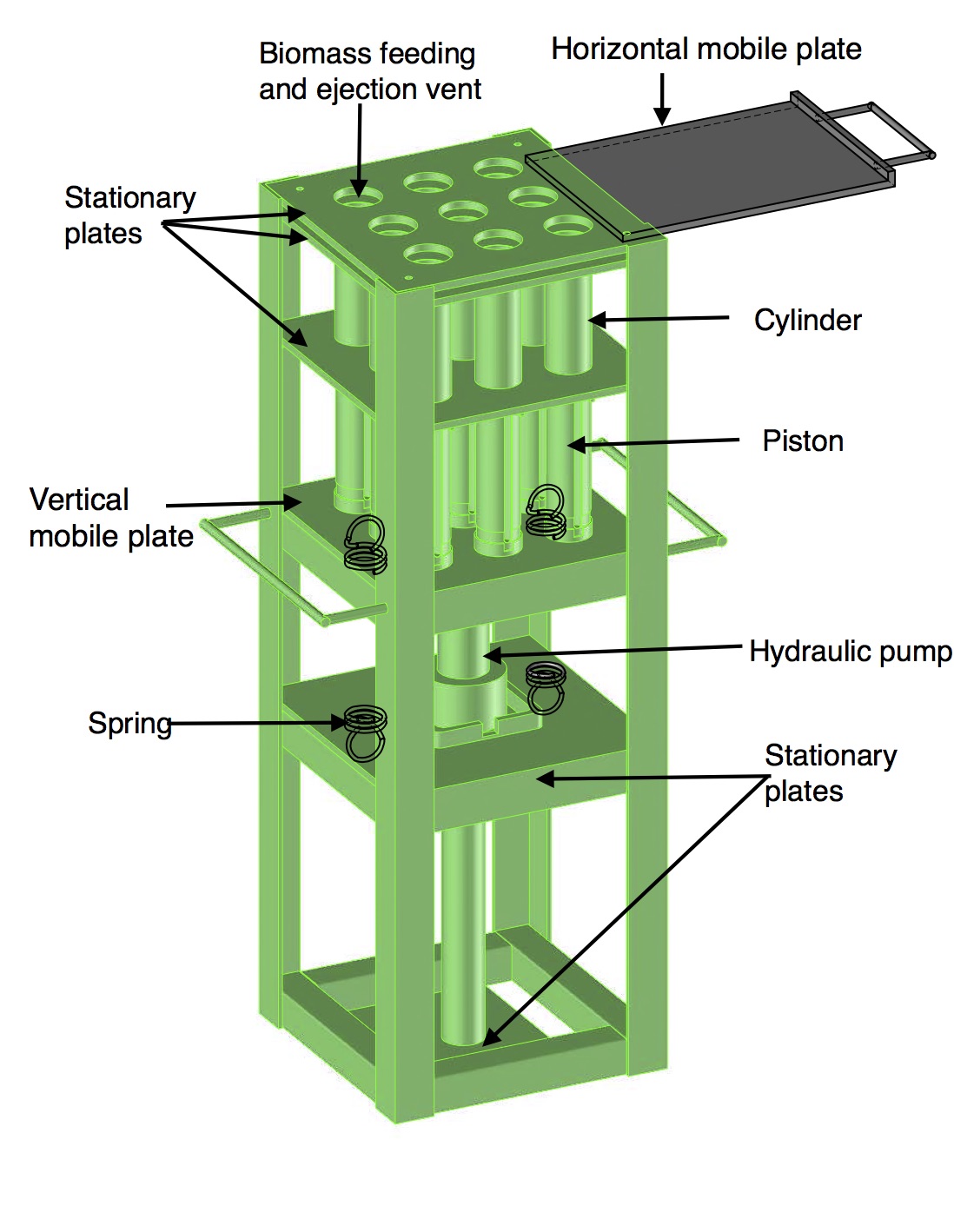

AfricaRice recently developed and tested the AfricaRice Multi-Piston briquetter. The equipment is a manual briquetting machine that can produce 45-144kg briquettes/day (11% moisture content) depending on the type hydraulic system (Stargold or Yale jack). The briquetter can be use both carbonized and non-carbonized biomass.

AfricaRice Multi-Piston Manual briquetter

The protocol for briquette production can be accessed here

The AutoCAD drawings of the equipment can be accessed here

For more information get the following publication:

TECHNOLOGIES DEVELOPED BY AFRICA RICE CENTER IN COLLABORATION WITH PARTNERS ARE PUBLIC GOODS. KINDLY ACKNOWLEDGE THE AFRICA RICE CENTER IF YOU USE ANY ON THE TECHNOLOGIES DESCRIBED HERE.